Sophie Thomas on product design and sustainability

We met Sophie Thomas to discuss how redefining waste can help create a more sustainable world.

Waste is a design flaw. That’s the mantra that campaigner and designer Sophie Thomas lives – and works – by. Her work to redefine product design with sustainability at the forefront has made her one of the leading experts in her field. We met Sophie to discuss how rethinking our approach to product design can help create a more environmentally-conscious world.

“Know what you believe in and have the conviction to be vocal about it”

The Central St Martins and Royal College of Art graduate has been championing sustainable design since she founded Thomas.Matthews with fellow designer Kristine Matthews back in 1997. Now, she’s also a chartered waste manager, the director of circular economy at Useful Projects, a member of the URGE collective and a WRAP trustee. That’s when she’s not collaborating on activist art projects or putting on her waste collector hat for a day.

The aspiring garbologist (one who studies waste) got a taste for activism from an early age. “My sustainability compass came long before my design compass. I was brought up in a quite political, quite activist family. [They taught me to] know what you believe in and have the conviction to be vocal about it.”

Her political upbringing led her to activism, but it’s her creativity that paved the way for her future career. “I would actually say that [design and sustainability] are kind of woven together, which makes them very hard to disentangle. I wanted to be an activist and, you know, stop boats, oil tankers, and become a part of the Greenpeace crew. And then I realized that my – for want of a better phrase – ‘superpower’ was actually creativity.”

Sophie first mobilized it through visual communication. “I’ve always been very fascinated with graphic activism and creating a voice for things that don’t have voices or citizens that aren’t able to speak. That kind of intertwining of using the power of the voice but in a graphical way took me into design.”

A voice for waste

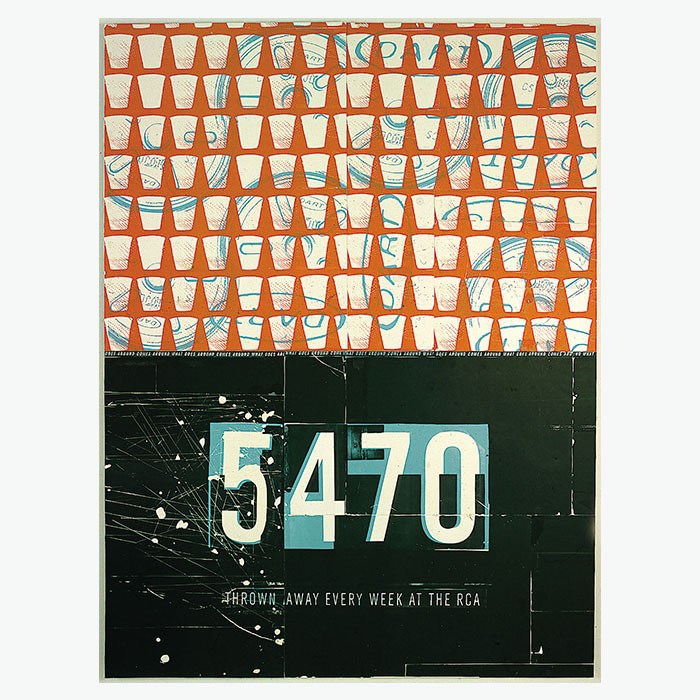

She set off to study graphic and communication design at some of the most prestigious universities in the UK, where she met future co-founder Kristine Matthews. Together, they put their skills at the service of sustainability with powerful projects. The first one, “what comes around goes around”, took root at the Royal College of Art. “We collected a week’s worth of waste from the canteen and hung it in the hall, showing people visually what a week’s worth of waste was and what happens to it. The aluminum wasn’t recycled at that point, and neither was glass. We spent a lot of time going through the waste and analyzing all the data, going through all the catering records.

“Then, we created a mug that cost two pounds and would get you a three pence discount on your coffee every time you used it – which was the price of a polystyrene cup. With that money, we bought the right bins and then talked to the waste management company to set up the recycling. It’s not just about the campaign and doing something that’s at surface level. You actually have to dig deep into the data and try to change a system – this still applies to all the work that I do. It’s very much about highlighting and activating as well as really doing your research and your lifecycle analysis. That’s the exciting bit for me as well. That’s part of the design, interrogation and investigation project.”

The duo also worked with Friends of the Earth to create “No shop” in 1997. For the launch of “Buy nothing day” in the UK, they set up a shop that sold nothing on the high street, encouraging people to disconnect from their consumer identity and reflect on their purchase habits.

More than twenty years later, art and awareness still work hand in hand for Sophie Thomas. Her project with award-winning homeware designer Ella Doran, Clean up Camo, turns waste picked from polluted beaches into beautiful, almost abstract patterns that cover sustainably-made scarves, cushions and other accessories. She also works with Common Seas to better understand how to design so waste doesn’t get into the ocean in the first place – principles she applied to the collection.

“Clean up Camo was very much about the medium being part of the message – again, taking the concept of activism even into the material. We spent a long time looking at the supply chain. We worked with lifecycle analysis specialists and ended up with a post-consumer polyester material on which we could do waterless printing – which really helps because textile dyes are terrible for water pollution.”

The dye sublimation process created other waste – but much more manageable one. “It’s a print process that works with a heat process. Effectively, you have a full color print onto a paper substrate and apply it to weld the ink into the materials. But you end up with the waste paper afterwards, so we took all of that back and made all the packaging from it as we had refused all the plastic sleeves but still needed to supply protection to the product – so there’s a beginning of closed loop.”

It was also essential to think about the product afterlife. “When you finish with your product in 10-15 years, we can take it back and get it fully recovered because they’re all one material. We’ve really researched everything – every zip, every piece of thread is a polyester or PE derivative so we can take it through one system.”

Circular economy is setting the table for a sustainable world

The principles Sophie Thomas follows in her own practice are those she’s trying to advocate for. The pressure of production and cost often veers designers away from the concerns surrounding sustainability and product afterlife. This leads them to mix materials and methods, creating products that can’t be processed and recycled properly. A headache for consumers, who, despite their best efforts, often end up popping their finished products in the wrong bin.

“As designers, we follow briefs, which tend to be getting the best answer to something for the cheapest price. So we’re not really designing for reuse or repair or recovery of materials. Weirdly, that would make it more expensive. And it’s really crazy when you look at the balance of everything in the account, the economies of scale are very skewed. That’s because in the linear economy, we discount so many things that are just hidden or not passed on in the material cost. The challenge is how we change that.”

The core concept behind circular economy is giving a second (and third, and fourth…) life to objects. How can designers implement this principle in the development process? “It’s one of the best design challenges because you’re not taking things for granted. What happens if you don’t use that specific material? I often hear designers saying, ‘well, I’m just responding to the brief, I can’t do much about it’ – but I would suggest that’s not true. You’re specifying the materials, you’re specifying the colors, you can actually influence a lot of those things. And you can also educate yourself in order to, if not persuade your clients, find other clients who are interested in it.

“It’s such an interesting challenge for a designer because it really pushes you in different ways. It makes you a bit leaner as a designer because you think more laterally and you think more carefully about all the different steps or processes so you don’t just pull something off the shelf. You think about the provenance of it. You think about the specifications of how you put it together. You think about the longevity of it. And that makes you think better, more aware of how your product is out there in the world. So you don’t just become another cog in the machine, churning stuff out.”

“Sustainability should be a foundation principle for all designers”

Education is key to moving towards a more responsible product design process – and a more sustainable model in general. “Sustainability is usually taught as a module but it should be a foundation principle for designers, with circular economy as its application. It’s not even a design course, it’s economics. What do you do if you have to go head-to-head with a model of profitability based on unit costs and unit selling? How do we create an opposing model around refilling, servitization, leasing? How can you make that more compelling than the unit product?

“They say it’s eighteen times more profitable to keep your existing customer through the servitization model than to try to get a new one. It’s that much more expensive to get new customers all the time. The challenge is that it takes longer to see the benefit, so it’s much quicker to sell something and get your profit straight away rather than build a long-term relationship with your customers. It’s just a different way of thinking.”

Today and tomorrow

When it comes to the future, Sophie Thomas remains hopeful but knows there’s still a lot to do. Since she worked on The Great Recovery, a project running from 2012 to 2016 which considered the challenges of waste and the opportunities of a circular economy through the lens of design, things have started to (slowly) change for the better. “It’s there. It’s beginning to happen, you can see it. On the one hand, there’s more stuff in the world, and the same companies we were working with ten years ago are still grappling with it now.

“On the other hand, now we have the new repair laws and repair indexes. That makes us go head-to-head with a lot of issues around, like how things are glued together in electronics, the way clothes are produced… It’s very important when you know the average use life of a piece of clothing is about seven times in the UK before it goes to waste – and our disposable attitudes are accelerating. But we have to be positive and hopeful about it to understand how to address this challenge. I think the main thing as a designer is not to create fluff; stuff that is just not relevant or important.”

One of the misconceptions Sophie fights against in her work is the belief that sustainability focuses solely on the production, when in reality the life and afterlife of a product are crucial to defining its environmental impact.”It’s effectively about form and function. If you create something out of this sustainable material, but it doesn’t last as long, or it breaks, is it really the best material? I have this thing about people giving you a paper bag instead of a plastic bag. I mean, I don’t like plastic bags at all, you know, and hopefully you bring your own bag, but sometimes you get paper bags and they don’t even last. You just walk down the street and a handle falls off or it starts raining. And to me that’s a design flaw as well.

“From a perspective of the lifecycle of how that paper bag has been made, you probably find that the energy required to get that tree into a paper bag is bigger than we think. The UK based NGO Green Alliance estimate that swapping all current plastic packaging for other materials on a like-for-like basis could almost triple the UK carbon emissions. But due to the “no plastic” drive at the moment – because we see the wasteful streams running into our seas (and now in our blood) – we see businesses react by substituting, when actually, the message should be ‘bring your own’, don’t take a bag at all.”

For her, changing our perception of value and where it lies is key to understanding a circular economy. “Designers should be very holistic, they should really understand the provenance and where that material has come from; how much impact it has had. And they should also understand that their design is a blip in the material lifespan. That material is going to go on and on and on, and you want it to go on and on and on because that’s the value. The value is not in your blip, the value is in the material.”

“Waste is just an untapped resource in the wrong place”

Sophie is fascinated by waste materials. “My mantra is ‘waste is a design flaw’ because effectively, you’re not designing the whole, you’re not designing for a system. But currently, we have a lot of waste, so how can we get it back and start using it? We need to redefine what waste is. It’s just an untapped resource in the wrong place, we need to get it back into the workplace. Again, Clean up Camo is using post-consumer materials. This has been through the [waste] system already and it is a great material.”

View this post on Instagram

“As a designer, you need to imagine the brief includes the third and fourth lives of your product. You need to understand what happens after its intended purpose. It’s about not creating extra lamination or another material on top of it or not glueing it together so it’s impossible to take apart. Then you need to think about the purity of that product. If you put loads of dye in plastics, for instance, or preservatives and flame retardants – these all add contamination to the material stream.

“In the end, it’s a big balancing act of the two sides of manufacturing and un-manufacturing, and you need to understand how the design dictates the least impactful way of getting it back into the system in its highest value possible. So it’s about understanding the potential of its future lives.”

A change for the better

To find better, greener materials, the challenge often happens to be sorting the wheat from the chaff. Innovative, self-labeled “eco-friendly” materials don’t always deliver when looking at their overall environmental footprint. Sophie insists on the importance of scrutinizing the credentials of these materials when thinking about sustainable product design. Looking at the origin of the materials is key, but can be more complex than it seems. “Even for us, who benefit from a very good network, a lot of this information is hard to find. There are these massive global supply chains, often created in faraway countries, and they won’t give you that information because it’s part of their intellectual property, or they just don’t know and have never needed to ask.”

The research shouldn’t stop there, though. Balancing the materials themselves with their transportation impact, water use, and other key aspects of the production process is essential to making an informed decision. “It’s about understanding and getting as much data as you can. But the one thing I really believe is that as customers, we should all really be demanding more transparency of data of the provenance of the material and understanding where our stuff comes from, how it’s made, and what’s in it. Some of the conversations that I have are ‘oh my god, I can’t believe that particular material has X in it’. People just don’t know, they can’t see it.”

“We need to know where to look for answers, and we’re still woefully short of materials libraries. Designers call out for them but they’re expensive to run and hard to keep up to date. It’s a full-time job!” Creating a palette of materials was actually one of Thomas.Matthews’ first projects and this curiosity for materials still underlines all of the studio’s work.

“We should be using our creativity to make the world a better place”

Product design and sustainability are deeply intertwined, but they also intersect with other social issues. “If you look at the big industrial areas around the world, they’re usually right next to the most deprived populated areas. The land is so polluted, so it’s cheaper. There’s exploitation of resources and exploitation of people all bound together in this model of producing and making. It’s really depressing to think that we wait for a brief to design something new and shiny when actually we should be using our creativity to make the world a better place. Thankfully, there is a growing number of designers now doing that, you know, it does feel more optimistic.”

Ecover is one of the brands Sophie Thomas cites as best-in-class examples. “They’ve always been very interesting in the way they approached transparency right at the beginning, sharing their recipes for their products. They’ve always looked at recycled material in the packaging, and started offering refill decades ago. Now, they are pushing it again – a refillution! They’re thinking about the fact that I don’t want to buy a bottle with some liquid in it, I just want to be able to wash my clothes.”

View this post on Instagram

While Ecover has been around for over fifty years, she also mentions younger companies paving the way for a greener future. “I am also excited about new platforms like ClubZero, a returnable packaging offering designed to hold both hot and cold food and drinks. This new company partners with food and beverage retailers, brands, and catering companies to deliver and take back, wash and re-supply all packaging that instead of being disposable is reusable.

“My research has led me to discover companies making fascinating new materials that have the potential to completely disrupt. These innovations include MarinaTex, a new plastic film alternative made from fish processing waste and NexCupCycle, a material made solely from disposable coffee cups that has the potential to be as strong as other fibre composites.”

She also suggests that the rise of small batching and local manufacturing is a sign that businesses are going in the right direction. When it comes to bigger companies, she appreciates seeing more introspection and willingness to change in organizations.

This educational aspect of her work is one of her favorite parts. “My work involves a lot of research; it feels quite good to use this research to help someone. I’m open to spreading the word and yes, I can get on my little soapbox and tell everyone what to do,” she laughs.

Beyond product design

Working towards more sustainable materials and products involves working with the policies and infrastructures available. Sophie tells the story of a computer brand that launched an ‘eco computer’. “They effectively just clad the machine in bamboo, and when it got to the end of life, the sorting machine at the e-waste facility couldn’t identify the bamboo – it thought it was plastic. It ended up contaminating tonnes of waste that could have been recovered. The product actually ended up creating much more waste than if they had just left as it was.”

She sees the same issue with bioplastics. “People are jumping out on these materials, but in the UK, for example, we don’t have a recovery system that takes any of that material yet. Currently, if it gets into the recycling crate, it can potentially contaminate other plastics. And if it ends up in your composting bin, it will just have to be taken out, because the bacteria in the AD systems can’t deal with it.”

For Sophie, we should start by basing product design on existing infrastructures. Here, too, she insists on the importance of looking at the full picture. “With the infrastructure we have now, we’re woefully low on our recycling targets. For me, it’s about optimizing that, because this is the system we live in now. And then we should think about what infrastructures we do need to have in place to manage resources better. It’s often not in the designer’s space, but it’s something we can ask from the local authorities. It’s absolutely an issue of balancing policy, optimizing and designing together.”

Policies are getting better at addressing these issues. “There’s a lot going on at the moment. We’ve got the new extended producer responsibility (EPR) regulations coming out, and the Environmental Bill is pushing through lots of changes. Everything will be impacted: product design, packaging construction, electronics textiles – there’s going to be a lot of very interesting stuff coming out in the next ten years or so. It’s a long term vision.”

“It’s so important to be aware of the regulation. With EPR, it’s very much starting with packaging. Things like deposit return schemes – taking bottles back and getting your deposit returned – are part of the extended producer responsibility. That means the producer pays in the first place. So actually, if you’re designing a product for a company, and you’re not being efficient, or you’re not thinking about your materials and they could potentially end up in the wrong bin or in an ocean, you might end up getting your client to pay for your bad design choice.”

You can learn more about Thomas.Matthews here and follow Sophie Thomas on Twitter here.

Keep in touch

Get design inspiration, business tips and special offers straight to your inbox with our MOOsletter, out every two weeks.